ՏԵԽՆԻԿԱԿԱՆ ՀԱՏԿՈՒԹՅՈՒՆՆԵՐ

| Արտադրանքի անվանումը | վարդակից եռակցման եզր |

| Չափս | 1/2"-24" |

| Ճնշում | 150#-2500#, PN0.6-PN400, 5K-40K |

| Ստանդարտ | ANSI B16.5, EN1092-1, JIS B2220 և այլն: |

| Պատի հաստությունը | SCH5S, SCH10S, SCH10, SCH40S, STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS և այլն: |

| Նյութ | Անժանգոտվող պողպատ:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo և այլն։ |

| Ածխածնային պողպատ:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 և այլն։ | |

| Դուպլեքս չժանգոտվող պողպատ՝UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 և այլն: | |

| Խողովակաշարային պողպատ՝A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 և այլն։ | |

| Նիկելի համաձուլվածք՝Ինկոնել600, Ինկոնել625, Ինկոնել690, Ինկոլոյ800, Ինկոլոյ825, Ինկոլոյ800H, C22, C-276, Մոնել400, Ալյումին20 և այլն: | |

| Cr-Mo համաձուլվածք՝A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo և այլն։ | |

| Դիմում | Նավթաքիմիական արդյունաբերություն, ավիացիոն և աերոտիեզերական արդյունաբերություն, դեղագործական արդյունաբերություն, գազի արտանետումներ, էլեկտրակայան, նավաշինություն, ջրի մաքրում և այլն: |

| Առավելություններ | պատրաստի պաշար, ավելի արագ առաքման ժամանակ, հասանելի է բոլոր չափսերով, անհատականացված, բարձր որակ |

Չափերի ստանդարտներ

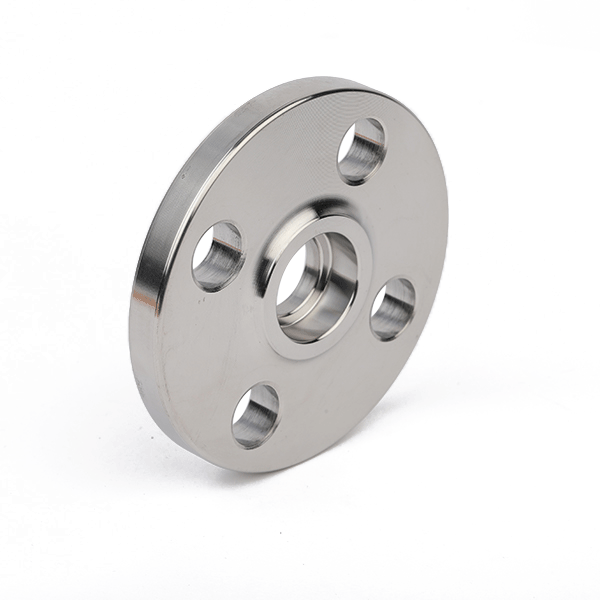

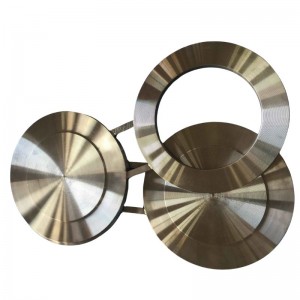

ԱՊՐԱՆՔՆԵՐԻ ՄԱՆՐԱՄԱՍՆ ՑՈՒՑԱԴՐՈՒԹՅՈՒՆ

1. Դեմք

Կարող է լինել բարձրացված դեմքով (RF), լրիվ դեմքով (FF), օղակաձև միացմամբ (RTJ), ակոսավոր, լեզվային կամ անհատականացված։

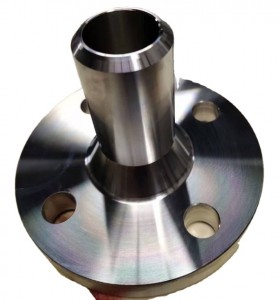

2. Խողովակի եռակցում

3.CNC նուրբ ավարտված

Երեսպատման մակերես. Եզրագծի մակերեսի մակերեսի մակերեսի մակերեսը չափվում է որպես թվաբանական միջին կոպտության բարձրություն (AARH): Վերջնական մակերեսը որոշվում է օգտագործվող ստանդարտով: Օրինակ, ANSI B16.5-ը սահմանում է մակերեսի ... միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի

Նշում և փաթեթավորում

• Յուրաքանչյուր շերտ օգտագործում է պլաստիկե թաղանթ՝ մակերեսը պաշտպանելու համար

• Բոլոր չժանգոտվող պողպատի համար նախատեսվածները փաթեթավորված են ֆաներայի տարաներով։ Ավելի մեծ չափի ածխածնային եզրերի համար նախատեսվածները փաթեթավորված են ֆաներայի պալետներով։ Կամ կարող են լինել անհատական փաթեթավորում։

• Առաքման նշանը կարող է պատրաստվել պահանջով

• Արտադրանքի վրա նշագրումները կարող են փորագրված կամ տպված լինել: OEM-ը ընդունվում է:

ԶՆՆՈՒՄ

• UT թեստ

• Ֆոտոթերապիայի թեստ

• ՄՏ թեստ

• Չափերի փորձարկում

Մինչև առաքումը մեր որակի վերահսկման թիմը կկազմակերպի NDT թեստ և չափերի ստուգում: Նաև ընդունում է TPI (երրորդ կողմի ստուգում):

Արտադրական գործընթաց

| 1. Ընտրեք իսկական հումք | 2. Կտրեք հումքը | 3. Նախնական տաքացում |

| 4. Կռում | 5. Ջերմային մշակում | 6. Կոպիտ մեքենայացում |

| 7. Հորատում | 8. Նուրբ մեքենայացում | 9. Նշում |

| 10. Ստուգում | 11. Փաթեթավորում | 12. Առաքում |

Հաճախակի տրվող հարցեր

1. Ի՞նչ է ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրը:

ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրագիծը եզրագիծ է, որն օգտագործվում է բարձր ճնշման կիրառություններում խողովակները միացնելու համար: Այն պատրաստված է կռած չժանգոտվող պողպատից՝ հեշտ տեղադրման համար նախատեսված վարդակաձև եռակցման միացումներով:

2. Ինչո՞վ են ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակավոր եռակցման եզրերը տարբերվում եզրերի այլ տեսակներից:

Ի տարբերություն այլ տեսակի եզրերի, ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված խորշային եռակցման եզրերը պահանջում են խորշային եռակցման միացում, որտեղ խողովակը տեղադրվում է եզրի մեջ և ներքին եռակցվում: Սա ապահովում է ամուր և արտահոսքից պաշտպանված միացում:

3. Որո՞նք են ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրագծերի օգտագործման առավելությունները:

ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակավոր եռակցման եզրերի օգտագործման հիմնական առավելություններից են բարձր ամրությունը, հուսալիությունը և կոռոզիոն դիմադրողականության գերազանց մակարդակը: Դրանք իդեալական են ամուր և ամուր միացումներ պահանջող կիրառությունների համար:

4. Ո՞ր ոլորտներում են սովորաբար օգտագործվում ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրեր:

ANSI B16.5 կռած չժանգոտվող պողպատից վարդակավոր եռակցման եզրերը լայնորեն կիրառվում են նավթի և գազի, նավթաքիմիական, քիմիական, էլեկտրաէներգիայի արտադրության և ջրամաքրման արդյունաբերություններում: Դրանք հարմար են բարձր ճնշման և բարձր ջերմաստիճանի կիրառման համար:

5. Կարո՞ղ են ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակավոր եռակցման եզրերը օգտագործվել գազային և հեղուկային կիրառություններում:

Այո, ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակավոր եռակցման եզրերը հասանելի են գազային և հեղուկային կիրառությունների համար: Դրանք նախագծված են անվտանգ միացում ապահովելու համար և կարող են դիմակայել հեղուկների լայն շրջանակի ճնշմանը և ջերմաստիճանին:

6. Ի՞նչ չափորոշիչներ են պահպանվում ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրերի արտադրության համար:

ANSI B16.5 կռած չժանգոտվող պողպատից վարդակաձև եռակցման եզրակալները արտադրվում են Ամերիկյան ազգային ստանդարտների ինստիտուտի (ANSI) կողմից սահմանված չափանիշներին համապատասխան: Այս չափանիշները ապահովում են, որ եզրակալները համապատասխանում են անհրաժեշտ որակի և կատարողականի պահանջներին:

7. Արդյո՞ք ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրերը հասանելի են տարբեր չափսերով և ճնշման վարկանիշներով:

Այո, ANSI B16.5 կռած չժանգոտվող պողպատից վարդակավոր եռակցման եզրերը հասանելի են տարբեր չափերի և ճնշման վարկանիշներով: Սա թույլ է տալիս ճկունություն և համատեղելիություն տարբեր խողովակաշարային համակարգերի և պահանջների հետ:

8. Կարո՞ղ են ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակավոր եռակցման եզրերը օգտագործվել բարձրացված և հարթ մակերեսային միացումների համար:

Այո, ANSI B16.5 կռած չժանգոտվող պողպատից վարդակաձև եռակցված եզրակալները հասանելի են ինչպես բարձրացված, այնպես էլ հարթ միացումների համար: Եզրակալների մակերեսները կարող են հարմարեցվել կիրառման կոնկրետ կարիքներին համապատասխան:

9. Արդյո՞ք ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրերը հարմար են բարձր ջերմաստիճանային կիրառությունների համար:

Այո, ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակավոր եռակցման եզրերը հարմար են բարձր ջերմաստիճանային կիրառությունների համար: Դրանք նախագծված են բարձր ջերմաստիճաններին դիմակայելու համար՝ առանց իրենց կառուցվածքային ամբողջականությանը վնասելու:

10. Ինչպե՞ս պետք է տեղադրվեն ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված վարդակաձև եռակցման եզրերը:

ANSI B16.5 կռած չժանգոտվող պողպատից պատրաստված ակոսավոր եռակցման եզրերը պետք է տեղադրվեն այնպես, որ խողովակը մտցվի ակոսավոր եռակցման մեջ և ներսից եռակցվի։ Կարևոր է ապահովել, որ միացման ամրությունն ու ամբողջականությունը պահպանվեն։

Ապրանքների մանրամասն ցուցադրություն

1. Դեմք

Կարող է լինել բարձրացված դեմքով (RF), լրիվ դեմքով (FF), օղակաձև միացմամբ (RTJ), ակոսավոր, լեզվային կամ անհատականացված։

2. Խողովակի եռակցում

3.CNC նուրբ ավարտված

Երեսպատման մակերես. Եզրագծի մակերեսի մակերեսի մակերեսի մակերեսը չափվում է որպես թվաբանական միջին կոպտության բարձրություն (AARH): Վերջնական մակերեսը որոշվում է օգտագործվող ստանդարտով: Օրինակ, ANSI B16.5-ը սահմանում է մակերեսի ... միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի չափի միջինի

Նշում և փաթեթավորում

• Յուրաքանչյուր շերտ օգտագործում է պլաստիկե թաղանթ՝ մակերեսը պաշտպանելու համար

• Բոլոր չժանգոտվող պողպատի համար նախատեսվածները փաթեթավորված են ֆաներայի տարաներով։ Ավելի մեծ չափի ածխածնային եզրերի համար նախատեսվածները փաթեթավորված են ֆաներայի պալետներով։ Կամ կարող են լինել անհատական փաթեթավորում։

• Առաքման նշանը կարող է պատրաստվել պահանջով

• Արտադրանքի վրա նշագրումները կարող են փորագրված կամ տպված լինել: OEM-ը ընդունվում է:

Ստուգում

• UT թեստ

• Ֆոտոթերապիայի թեստ

• ՄՏ թեստ

• Չափերի փորձարկում

Մինչև առաքումը մեր որակի վերահսկման թիմը կկազմակերպի NDT թեստ և չափերի ստուգում: Նաև ընդունում է TPI (երրորդ կողմի ստուգում):

Արտադրական գործընթաց

| 1. Ընտրեք իսկական հումք | 2. Կտրեք հումքը | 3. Նախնական տաքացում |

| 4. Կռում | 5. Ջերմային մշակում | 6. Կոպիտ մեքենայացում |

| 7. Հորատում | 8. Նուրբ մեքենայացում | 9. Նշում |

| 10. Ստուգում | 11. Փաթեթավորում | 12. Առաքում |

Խողովակային կցամասերը խողովակաշարային համակարգի կարևորագույն բաղադրիչներ են, որոնք օգտագործվում են հեղուկների միացման, վերահասցեավորման, շեղման, չափերի փոփոխման, կնքման կամ հոսքի կառավարման համար: Դրանք լայնորեն կիրառվում են շինարարության, արդյունաբերության, էներգետիկայի և քաղաքային ծառայությունների ոլորտներում:

Հիմնական գործառույթներ՝Այն կարող է կատարել այնպիսի գործառույթներ, ինչպիսիք են խողովակների միացումը, հոսքի ուղղության փոփոխությունը, հոսքերի բաժանումը և միաձուլումը, խողովակների տրամագծերի կարգավորումը, խողովակների կնքումը, վերահսկումը և կարգավորումը։

Կիրառման շրջանակը.

- Շենքի ջրամատակարարում և ջրահեռացում.Ջրամատակարարման ցանցերի համար օգտագործվում են PVC արմունկներ և PPR եռանկյունաձև ամրակներ:

- Արդյունաբերական խողովակաշարեր.Քիմիական նյութեր տեղափոխելու համար օգտագործվում են չժանգոտվող պողպատե եզրեր և համաձուլված պողպատե արմունկներ:

- Էներգիայի փոխադրում.Բարձր ճնշման պողպատե խողովակների կցամասերը օգտագործվում են նավթի և գազի խողովակաշարերում:

- HVAC (Ջեռուցում, օդափոխություն և օդորակում):Պղնձե խողովակների միացումները օգտագործվում են սառնագենտի խողովակաշարերը միացնելու համար, իսկ ճկուն միացումները՝ թրթռումը նվազեցնելու համար։

- Գյուղատնտեսական ոռոգում.Արագ միակցիչները հեշտացնում են ցողունային ոռոգման համակարգերի հավաքումը և ապամոնտաժումը։

-

չժանգոտվող պողպատից կռած գրկում համատեղ չամրացված եզր գ ...

-

Պատվերով LWN եզրակալ Ստանդարտ ածխածնային պողպատե Sta ...

-

ASME b16.48 Գործարանային վաճառք ածխածնային պողպատից 8-րդ նկար ...

-

ածխածնային պողպատից եռակցման պարանոցի տեսակ՝ 6 դյույմ ANSI դասի...

-

Չժանգոտվող պողպատ 304 304L 316 316L ASTM կռած t ...

-

Ստանդարտ ճնշման բացվածքի եզր կռած չժանգոտվող պողպատե...